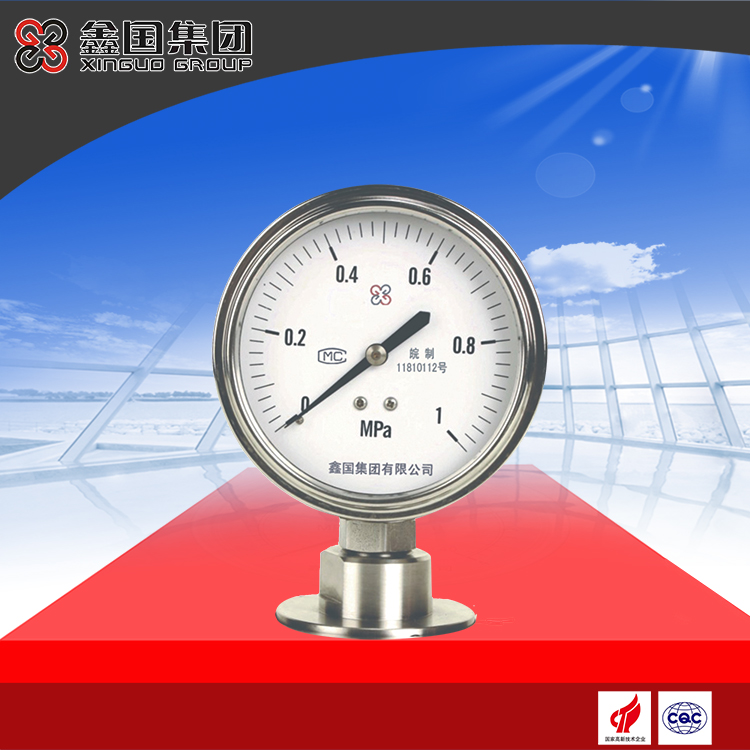

XG-Y-M Diaphragm Pressure Gauge

- tel:0086 550 7623999、0086 550 7623888

- fax:0550-7623199 ext 0

- email:xinguo@xinguo.net

Description

Y-M series diaphragm pressure gauge is suitable for measuring the pressure of liquid, gas or granular solid medium with corrosiveness, high viscosity, easy crystallization, easy solidification, high temperature, and it is necessary to prevent the measuring medium from directly entering the pressure instrument and prevent the accumulation of sediment and Easy to clean occasions. Diaphragm pressure gauges are mainly used in petroleum, chemical, chemical fiber, dyeing, pharmaceutical, alkali food and other industrial sectors.

Diaphragm pressure gauge structure principle:

Diaphragm pressure gauges are composed of various general-purpose pressure instruments and diaphragm isolators of different structures to form a closed system, which is filled with sealing liquid. When the pressure of the measured medium acts on the diaphragm, the diaphragm is deformed and compresses the diaphragm liquid in the closed system. , Due to the inherent properties of the sealing liquid, the elastic element in the pressure instrument produces corresponding elastic deformation and displacement, and the pressure value is displayed by the indicating device. When the rigidity of the diaphragm is small enough, the pressure indicated by the pressure instrument is close to the pressure value of the measured medium. .

Diaphragm pressure gauge technical indicators:

1. Temperature characteristics of diaphragm pressure gauges

Since the system of the diaphragm table is filled with sealing liquid as the medium for pressure transmission, the temperature influence of the diaphragm table is related to the expansion coefficient of the sealing liquid, the stiffness of the diaphragm and the temperature of the pressure-bearing part. When the operating temperature of the instrument deviates from 20±5℃, the influence on the low-range pressure instrument is particularly obvious. Generally, the temperature error of the pressure receiving part is not more than 1.0%/℃, so the temperature influence of the diaphragm gauge is generally the sum of the temperature influence of the general pressure gauge and the temperature influence of the pressure pressure part of the diaphragm isolator.

2. Liquid level difference of diaphragm pressure gauge

Especially for diaphragm gauges with soft connecting pipes, since the pressure-receiving part of the diaphragm and the installation position of the general-purpose pressure gauge are not on the same level, the influence of liquid level difference will occur, and more attention should be paid to accurate measurement.

3. Corrosion resistance of diaphragm pressure gauge

The corrosion resistance of the diaphragm pressure gauge can be ensured by suitable selection of the materials of the diaphragm, flange and sealing gasket of the part in contact with the measuring medium.

Diaphragm material: 0Cr17Ni12Mo2 (316); 0Cr17Ni14Mo2 (316L); Monel (Cu30Ni70); Hastelloy (H276C); Tantalum (Ta) and Fluoroplastic (F4).

Flange material: stainless steel 0Cr18Ni9 (304), 0Cr17Ni12Mo2 (316); stainless steel lined with fluorine plastic (316+F4).

Gasket material: nitrile rubber; fluororubber; silicone rubber and fluoroplastic.

4. Selection of diaphragm fluid for diaphragm pressure gauge

To ensure the reliability and safety of the diaphragm pressure gauge, the appropriate sealing fluid should be selected according to different purposes.