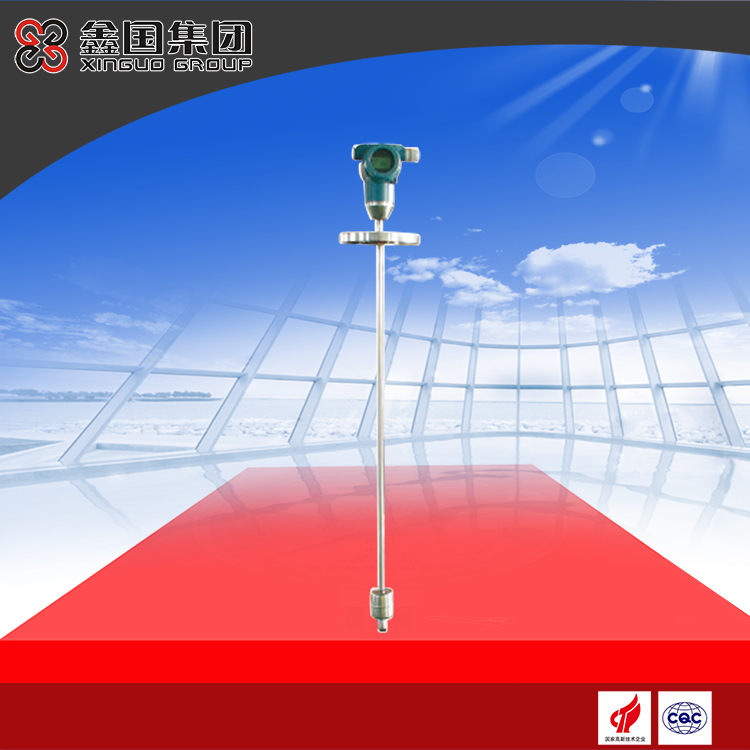

UZ-CZ magnetostrictive level gauge

- tel:0086 550 7623999、0086 550 7623888

- fax:0550-7623199 ext 0

- email:xinguo@xinguo.net

Description

XG/UZ-CZ magnetostrictive liquid level gauge, magnetostrictive liquid level gauge is a unique, extremely high-precision magnetic The sensor is more than 10 times higher than the traditional reed transmitter, and its basic structure includes electronic conversion components equipped with signal processing and induction electronic components installed in a stainless steel tube. The magnetostrictive liquid level gauge can be installed on the top of the tank as a whole or installed on the upper part of the tank through the lead-out pipe on the side of the tank. It is processed into a two-wire analog signal output by the microprocessor. Because the housing containing the electronic components is installed at the end of the sensor tube and has a special assembly structure, it can be used at high temperatures. It outputs a standard two-wire 4~20mA signal, and the user can easily adjust the actual measurement range of the liquid level on the spot through the three buttons on the instrument. The intelligent transmitter is designed to be easy to use and calibrate, and can also be used with UZ type magnetic liquid level gauge is used together.

●Detailed introduction of magnetostrictive level gauge:

1. Function introduction:

* called continuous measurement of tank level or interface

*Adopt the most advanced magnetostrictive principle

* The measurement accuracy is extremely high, the error is only 0.01% of the full scale, and the maximum error does not exceed 1.27mm.

* Can work under high temperature and high pressure. The maximum temperature can be selected to 250℃, and the maximum pressure can be selected to 10MPa.

*It has intrinsic safety and explosion-proof performance, and is suitable for use in flammable and explosive places.

* Output standard 4~20mA signal, with HART protocol communication.

*With optional temperature signal output function.

*It is installed on the top of the tank or on the side of the tank, and the integrated installation method is extremely convenient and simple, and the on-site adjustment is extremely easy.

2. Technical parameters:

◆Electronic transmitter:

Housing: Flameproof cast aluminum housing, including 1/2"NPT threaded connector and outlet connector.

Repeatability: 0.005% of the full scale, the maximum does not exceed 0.38mm.

Non-linearity: 0.01% of full scale, the maximum does not exceed 0.9mm.

Accuracy: 0.01% of the full scale, the maximum does not exceed 1.27mm.

Power supply: 10.5-36VDC

Polarity protection: diodes are connected in series in the port.

Output: Standard 4-20mA, can be manually adjusted in the field with SPAN and ZERO.

Damping: It can be adjusted on the spot with the button, and the adjustable range is 0.1~36 seconds.

Working temperature: ﹣40-65℃

Relative humidity: ≤85%

◆Sensor tube:

Materials: 316SS stainless steel, 20# alloy steel, Hastelloy, PTFE and plating options.

Working temperature: -40-65℃, optional / HHT can reach 250℃.

The highest working pressure: the standard can reach 6.5MPa at 148℃, and the optional / HHP can reach 20.4MPa.

Measuring range: 0.3~20 meters

Mounting: Standard 3/4″ NPT, Compression Threaded Fittings

Explosion-proof grade: EXibIICT5 standard