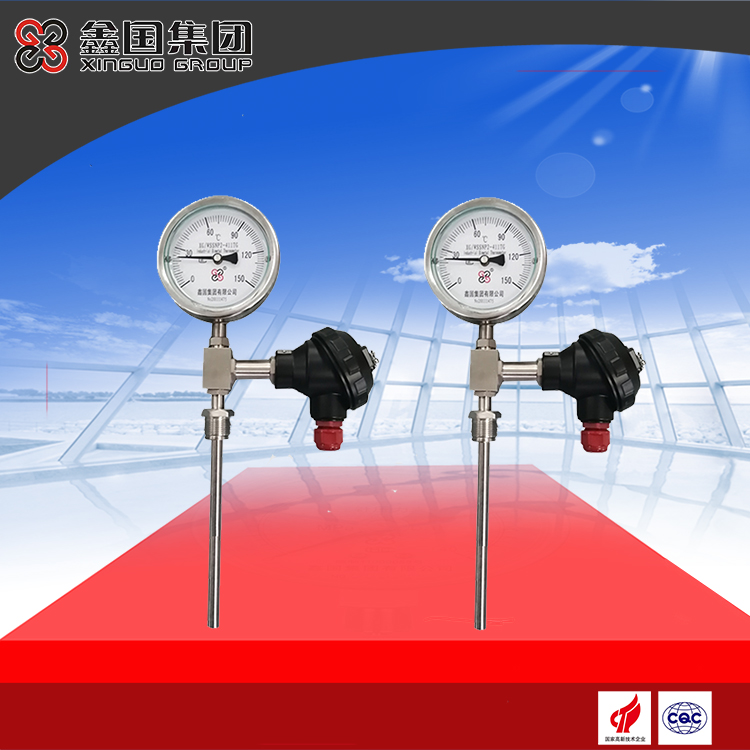

Stainless Steel Shock Resistant Remote Bimetal Thermometer

- tel:0086 550 7623999、0086 550 7623888

- fax:0550-7623199 ext 0

- email:xinguo@xinguo.net

Description

Model: XG/WSSNP2-411TG

1. Purpose:

Bimetal thermometer is a field detection industrial instrument suitable for measuring medium and low temperature. Can be used to directly measure the temperature of gases, liquids and steam. It is a bimetal thermometer with electrified contact, and can automatically send out a control signal to cut off the power supply or alarm when the working temperature exceeds a given value.

The bimetal thermometer has the advantages of no mercury, easy reading, robustness and vibration resistance, and can be widely used in industry and scientific research departments instead of industrial glass mercury thermometers.

Bimetal thermometers are divided into three types: ordinary type, outdoor type, and anti-corrosion type. The ordinary shell is plated with iron sheet, and the protective tube is made of stainless steel, which is suitable for general indoor use. The outdoor shell is made of aluminum and gold, the protection tube and the connecting column are all made of stainless steel, with good sealing performance, suitable for indoor and outdoor, general corrosion-resistant places. The anti-corrosion shell is made of all stainless steel, with a protective tube. The connecting column can be made of molybdenum-titanium material, and the connecting parts are all made of sealant, which can be used for the measurement of most corrosive media and gases.

Second, the structure principle:

The temperature sensing element of the bimetal thermometer adopts a multi-turn straight thread bimetallic sheet. One end is fixed, the other end (free end) is connected to the mandrel, and the pointer of the axial thermometer is directly mounted on the mandrel. The radial structure indicator needle is connected with the mandrel through the corner spring. When the temperature changes, the free end of the temperature sensing element rotates, and the pointer rotates through the mandrel to indicate the change value of the temperature of the measured medium on the dial.

Electric contact thermometer, the pointer is equipped with a moving contact, and the fixed contact is installed on the industrial pointer. The contact rotates with the temperature change. When the temperature reaches or exceeds the set value, the contact is closed to send a signal to achieve the purpose of automatic control and alarm.

3. Features of bimetal thermometer:

The thermometer is regularly maintained and repaired under normal use. Normally every six months is better. Electric contact thermometers are not suitable for working under strong shock, so as not to affect the reliability of the contacts. A variety of bimetal thermometers are not suitable for measuring the temperature of the medium in the open container, and the live contact thermometer is used in the control circuit of the occasion where the work is more shocking.

During storage, use, installation and transportation of the bimetal thermometer, care should be taken to avoid collision with the protection tube, and the protection tube should not be bent or deformed, and the watch should not be used as a wrench.

The length of the bimetal thermometer protection tube immersed in the measured medium must be greater than the length of the temperature sensing element. The normal immersion length is greater than 98mm, and the immersion length of the 0-50°C range is greater than 152mm, which can ensure the correctness of the measurement.

The advantages of bimetal thermometers are fast response, small size, good linearity and stability.

Four, installation and fixed form:

In order to meet the needs of actual production, bimetal thermometers have different installation and fixing forms: movable external threaded pipe joints, movable internal threaded pipe joints, fixed threaded joints, ferrule threaded joints, ferrule flange joints and fixed flanges.